The performance and stability of your skateboard rely on the type of trucks you use and how well you maintain them. They are part of the custom board every skateboarder owns.

Choosing the correct ones for your needs allows you to perform the tricks and turns you enjoy doing and give your skateboard a custom look.

Let’s take a look at different skateboard trucks sizes so you can make the best decision!

Anatomy of a Truck

1. Baseplate

This is your skateboard’s foundation; it holds the pivot cup and the kingpin to the board using four bolts.

2. Kingpin

Goes through the bushing (it’s the big bolt), holding the parts that make up the skate truck in place. These need to be heavy-duty and solid to control the pressure placed on the bushings. The pin can be solid or hollow depending on the board’s weight you need.

Kingpin is held in place by kingpin bolts (they are adjustable and give the control you need for tricks.) The nuts on the kingpin use a 9/16 inch wrench socket (this is standard.)

3. Bushings

Lets the skateboard pivot and turn effortlessly, located on the kingpin between the hanger and the base plate. Most are made of Polyurethane.

4. Axle

Attaches the wheels in the shape of a long pin that goes through the hanger to each wheel. Each brand of the axle has a measuring scale. You want the axle to be the width between the wheels (or as close as possible.)

5. Axle Nuts

Used to keep your wheels onto the axle.A 3/8 inch socket will come in handy for axle nuts.

6. Washer

Helps to evenly distribute the forces on the board. These discs are made of metal and located below and above the bushings. After a turn, the washers make sure your skateboard goes back to its starting position.

7. Speed Rings

Are placed between the bearings and hangers/bearings and axle nuts to stop the bearings and other components from grinding together. Their small size matches the core of the bearings.

8. Hanger

Is the most significant part of your skateboard. It is the metal, triangle-shaped part of the skateboard that the axle goes through.

Skateboard Trucks Sizes Guide

The most important decision made will be the trucks you use on your skateboard!

What Are They Made From?

Choose the truck’s material based on what you are doing with the skateboard. You are going to want a durable material when you do tricks.

Trucks come in different types of metal, like brushed and non-brushed steel, titanium, brass, magnesium, carbon fiber, and aluminum.

The Right Width

-

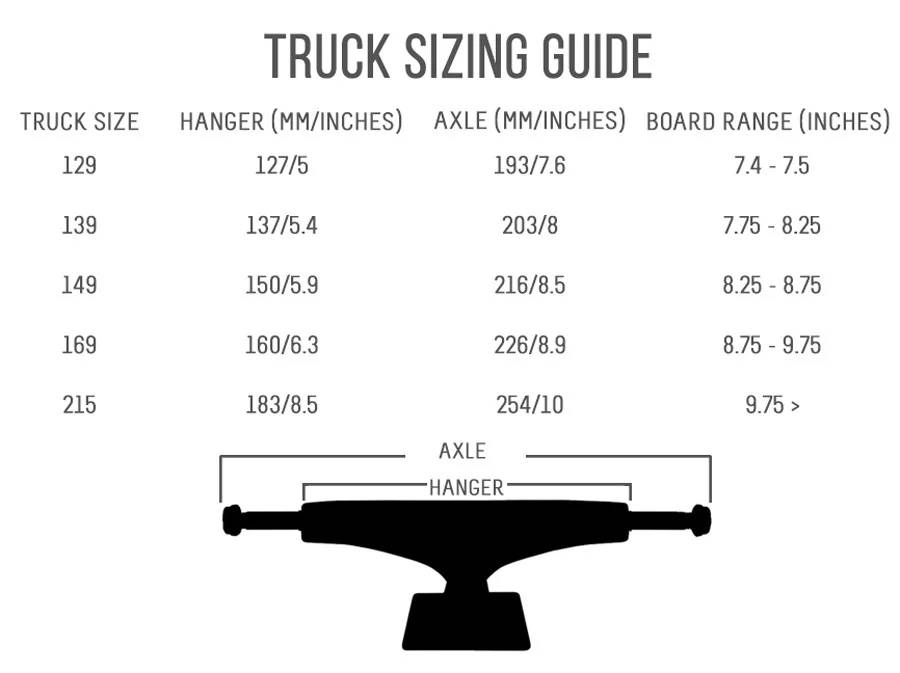

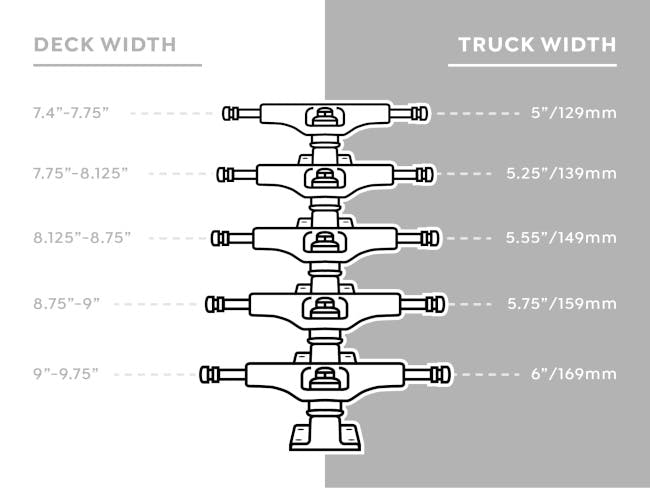

Axle Width (outer width):

The width of the axle (wheel to wheel.) You want the trucks to be the width of your skateboard (too wide will affect the center of gravity during flips and make the board feel all wrong.)

Decks wider than the trucks are no big deal and won’t affect it.

Example – 7.875″ x 8.125″ axle (wide truck) is perfect for an 8″ deck.

-

Hanger Width (inner width):

Even though the skateboard is described using hanger width, the manufacturer measures by the axle width.

There are no standardized truck sizes, making a choice all the more confusing!

The Right Truck Profile

The Low Truck

Pros

- More stability

- Better for grinding

- Less weight

- Ability to flip board faster, esp with smaller wheels

- Quicker to pop, more responsive due to lower center of gravity

Cons

- Larger wheels increase wheel bite

- Less kingpin clearance

- Smaller turning radius affects carve

The Mid Truck

Pros

- Great for street and park riding

- Good choice if you aren’t sure which truck to purchase.

Cons

- There are no real cons; they are a good choice when you’re not sure if you should use a low or high truck that lets you do the same things you would do with low/high trucks.

The High Truck

Pros

- Perfect for taller people and transition skating

- Less wheel bite; lets you turn wider

- Tighter turning radius and more pivoting room

- Bigger angles with better pop

- Harder tail snap

Cons

- Less stability when grinding worsens on circle rails

- Weighs more (no real effects)

The Hollow Truck

Pros

- Lightweight

- Pops higher

- Flicks Faster

Cons

- Less strength

- Less durable

- Doesn’t hold up well under tight pressure

- Doesn’t hold up well under high impact tricks

Different Profile Wheels

High – Best for large wheels, made for cruising the streets and when carving. A 56mm+ wheel size works best.

Mid – Best for mid-size wheels, work best for street and park skateboarding. A 53 – 56mm wheel size works best.

Low – Best for small wheels. Offer greater stability for tricks or flips. A 50 – 53mmwheel size works best.

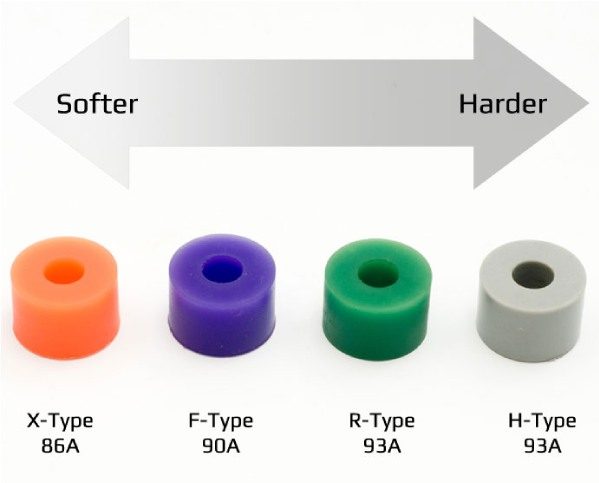

Bushing Hardness

The bushing is pre-installed in the truck and is a softer polyurethane. They can wear and need to be replaced so you can carve, do tricks and turn as you want to.

How hard the polyurethane is will determine how your wheels respond and the board’s stability.

How hard you have to work to make a turn, the board’s stability, and the truck’s stiffness depend on the hardness (durometer) of the bushing.

Hardness varies by manufacturer. Durometer is determined by a number and double AA’s (98AA). The higher the number, the harder the bushing.

Choosing a Cone Bushing (cone-shaped or tapered) creates a more responsive truck, a Barrel Bushing (flat) creates a less responsive truck. Some bushings are universal; you will have to check the package to identify these.

Adjusting the Steering

Using a skate tool is the easiest way to adjust (loosen and tighten) the kingpin. This affects the ease of turning the skateboard.

Be careful not to make the kingpin too tight, or you can ruin the bushings.

Trucks that are too tight will create instability and cause wheel bite (the wheels rubbing on the deck mid-trick making it stop), which could be dangerous.

Trucks – Wide

Pros

- Offer more stability

Cons

- Not as responsive when making large turns

- Less comfortable ride

- Need to push wider (feet can hit the wheels)

- Wear and tear on axle and axle nut, especially if you flip the board

Trucks – Narrow

Pros

- Small

- Weigh less

- Moment of inertia is smaller

Cons

- Fells like you are boarding on carpet

- Deck blocks the view of the wheels

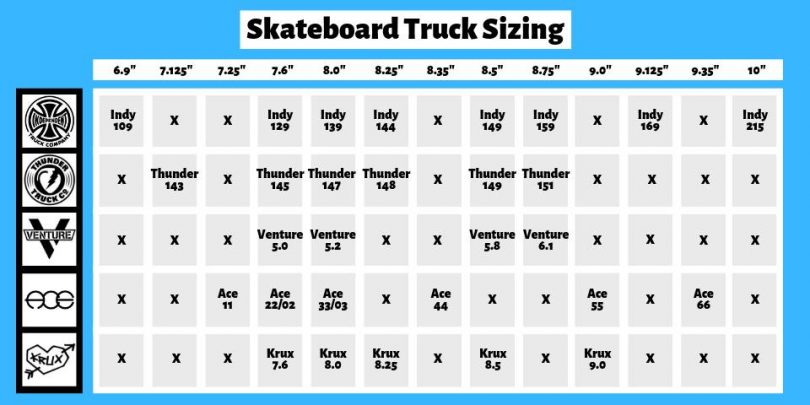

Does Each Brand Have a Different Truck Measurement?

Unfortunately, they do! Be sure to check your measurements against packages and sizing charts by the brand to get the best trucks for your skateboard.

Choosing the Truck Size For You

- When choosing what truck size for your skateboard, you will need to measure the width of your board

- Choose the brand of truck you want, compare the width to the chart, and pick out the right truck using the width

- Choose the right profile for your skateboarding needs

- Decide if you want a solid or hollow truck

- Choose the material you want for your truck

- Double-check the size to make sure you have the right truck before purchasing

FAQs

1. Are light trucks any good?

Ans. Light trucks are frequently stronger because they are forged and not cast, creating a lighter and stronger baseplate. Lighter trucks offer the ability to do tricks and maneuvers higher and faster.

Leave a Comment