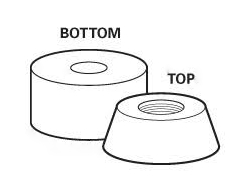

Skateboard trucks cannot function without bushings. There are two bushings on every truck – the top bushing faces the street, and the bottom faces the board.

Polyurethane is used as a material in bushings, just like skateboard wheels.

You will find bushings in a wide variety of colors, shapes, and hardness levels. Listed below are the various bushing types so that you can select the right type for your application.

Skateboard Bushings: What Are They?

Kingpins are attached to your truck with rubber plastic bushings. The polyurethane shafts enable you to pivot and turn your board.

You need to consider what kind of skateboard you ride, how heavy you are, and how stylish you are when choosing skateboard bushings.

Generally, skateboard bushings should be chosen according to:

- If you wish to skate street or do tricks, choose bushings in the shape of cones/barrels or cones/cones.

- When skating in vert, bowl, and park, use bushings that have cones or barrels.

- Longboard bushings need to be softer so that carving is possible.

- There are stiffer bushings needed for downhill and racing that offer more stability

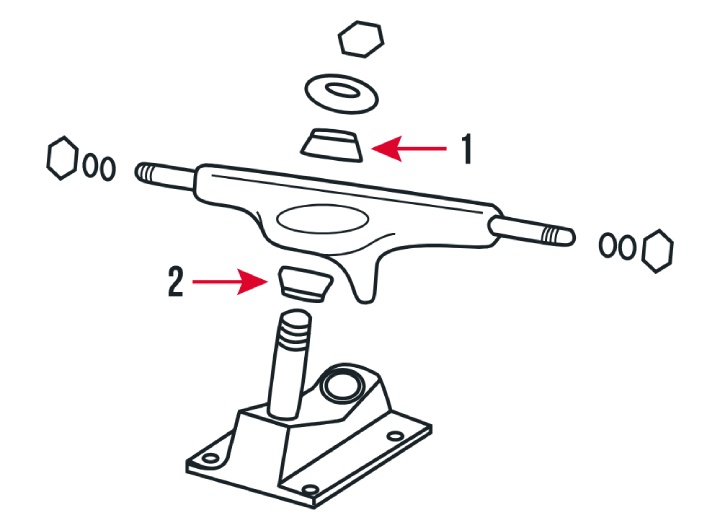

Skateboard Bushing Components

1. Bushing Washers

The bushing washers on each skateboard truck fit underneath the bushings. To install them, simply slide them onto the kingpins. The purpose of using washers is to stop the bushings from becoming deformed when there is pressure added to the trucks.

Several bushing washers are included with skateboard trucks. The washers are similar in size in most sets. The top bushing may be provided with two small washers, while the bottom may have two larger ones.

According to the setup, the kingpin should be built up as follows: washer on the bottom first, then bottom bushing, bushing seat, then add the top bushing, then the top washer, and finish with the lock nut.

A bushing washer can have flat edges or be slightly cupped. Bushings with flat washers have a greater range of lateral motion, which allows them to stretch more.

As a result of cupped washers, bushings cannot move freely, preventing any deformation. Therefore, cupped washers have a higher resistance than flat washers.

For your bushing washer to function correctly, it must match the shape of your bushing. Furthermore, both cupped washers and overly soft bushings should not be paired together, as the washer edge can damage the bushing and cause it to wear.

2. Bushing Seats

Around the hanger opening, bushings sit in an indentation called a bushing seat. Through the opening, the kingpin is inserted, and then the bushings are attached.

Under the pressure of riding, bushing seats support and prevent the bushings from being compressed too much.

Bushing seats can be either open or restrictive. Restricted bushing seats have taller walls and are enclosed, so their bushings fit tightly.

The bushing seats in open bushings do not have as deep a recess as those in closed bushings, meaning less compression of the bushing seat occurs.

You must choose the right bushings for your seats regardless of the type of bushings you select.

A bushing seat’s tightness depends a lot on what style of skateboarding you do and what style of bushing you use.

How Do Bushings Work?

Bushings come in different shapes and hardnesses and are made of polyurethane. They greatly impact the way your skateboard feels and performs.

Based on how hard, how heavy, and how much you lean, bushings help you steer. Turning or carving causes your bushings to compress and the hangar angle of your truck to change.

A low-quality bushing will have fewer advantages over a high-quality bushing, such as greater responsiveness and more time for rebound.

If you’re shopping for a new set of bushings, consider getting quality bushings to increase rebound. Not only will they last longer, but they’ll also provide a smoother, more responsive ride.

There is a roadside and a board side. One faces the road, and the other faces the board. The weight is mostly distributed to the bottom bushing as it is closest to the board.

As you steer or compress the bushing, it carries most of the force.

On top, it is less stressed and basically supports the bottom bushing while helping to keep your truck together. Afterwards, the top bushing takes over once the bottom bushing has reached maximum compression.

Skateboard Bushing Types

1. Cone/Barrel Bushings

A cone/barrel bushing, also called a conventional bushing or a standard barrel is the most common shape for skateboard bushings. Bottom bushings have barrel shapes to firmly fit into the bushing seats.

Decks with conical top bushings are easier to carve because of the lean they create. The bottom of conventional bushings is often equipped with higher durometer tougher bushings to maximize their capabilities.

2. Barrel bushings

The most common bushing type for all riding styles is barrel bushings, which have the same width on top and bottom.

Due to their larger mass and surface area, barrel bushings are favored by the skateboarding industry due to their stability and responsiveness at fast speeds.

Tall barrels are not as common as they are only for certain trucks like Bennett and Ronin and other types that offer a larger clearance.

3. Double barrel

Fast longboard freeride and downhill speed freaks will love this. With so much stiffness, you will be safe while traveling at high speeds.

To increase stability and rebound, use cup washers with them. Carving and slalom are not recommended.

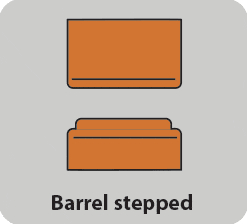

4. Barrel and stepped bushings combination

If the bottom of a truck has stepped bushings and a barrel on top, the truck is extremely stable.

Longboarding downhill, where stability takes precedence over sharp turns, is a good choice.

With the stepped bushing, a stable ride is provided by stiffness and lean resistance.

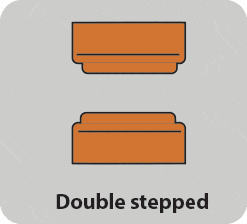

5. Double stepped bushings

For trucks that are very tight, choose double-stepped bushings. Due to the shape they have they are able to create lean resistance when you have a softer type of bushing installed.

The surface is larger than the barrel shape, but the top has an indentation. Since stepped bushings have a similar shape to stepped barrels, they are also called stepped bushings.

6. Insert bushings

To put it simply, insert bushings are designed with washers integrated into them. The bushing equation is simplified by eliminating the need for washers. Traditional kingpin trucks typically use these bushings.

7. Hourglass bushings

The bushing offerings of some manufacturers can be quite creative that often makes choosing the right bushings confusing.

Hourglass bushings are exactly as their name describes, shaped like an hourglass. The result is a less stable but leaner ride.

In the Hourglass category, we suggest treading lightly if you’re a beginner. For those who are not beginners, give the hourglass shapes a try.

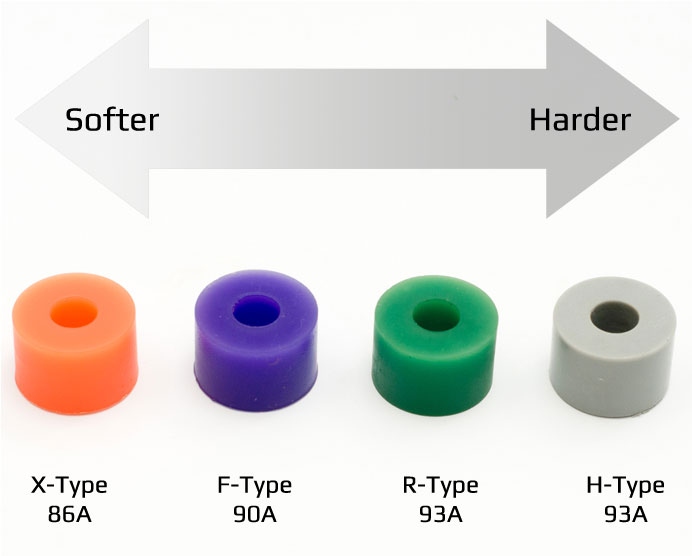

The Durometer

Durometers are used to measure bushings. Some companies are happy using the scale of Durometer A, while others prefer to go with the B-scale.

With durometer A you are pretty limited when it comes to scaling. With durometer B, harder wheels can be produced with the scale still being understood.

There is no such thing as 104A on the official A-scale, which runs from 1 to 100. So, 84B seems more appropriate. Just remember that the A scale runs 20 points higher than the B.

Hardness

The hardness comes in 3 grades: soft, medium, and hard. Each category has varying levels of hardness. The soft level of the bushing’s durometer is less than 90A or 70B. Bushings with these levels compress the easiest and turn the best.

Those who prefer loose trucks or who are lightweight skateboarders should consider them. These aren’t for speed freaks because the trucks wobble when they get unstable.

Hardness ranges from 90A (70B) to 96A (76B) for medium bushings. While still being responsive, these are awesome all-around and great for skateboarding.

Durometer 96A (76B) and higher is what hard bushings are made of. This type provides the greatest amount of stability but makes turning much more difficult.

Consider harder bushings if you’re heavier. Tighter trucks and faster speeds are also ideal for these bushings.

How to Break in Bushings?

Get a mini ramp or skate on flat ground for your first few sessions. After the bushings have broken in a few days, adjust the trucks.

Once your board feels normal-with no pulling to a particular side or any tightness noticed, you can tighten the trucks just as you would before riding.

Leave a Comment